Production

Quality

Assurance

Quality

Assurance

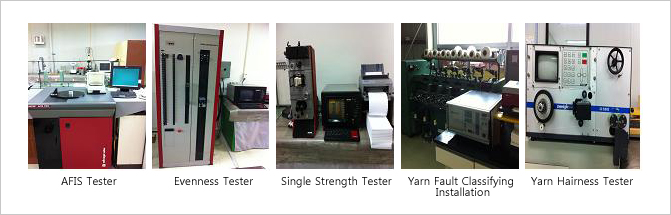

In all products, quality is a decisive factor in product value. Therefore, we have performed quality

control on all materials from raw materials to final yarn product in a scientific & systematic manner.

Using the below mentioned testing machines, we have always regarded the best quality as our top

priority to keep manufacturing high-quality products and achieve customer satisfaction.

| TESTING MACHINES | TYPE | PURPOSE | PROCESS |

|---|---|---|---|

| Electric Balance | EL-120HA | Weight test | All processes |

| Grain Balance | EK-120A | Count & Weight test | All processes |

| Drying Oven | Measurement of Moisture | Raw cotton, Yarn | |

| AFIS Tester | AFIS PRO | Cotton Analysis test | Raw cotton, Carding |

| Evenness Tester | Uster Tester 3 | Measurement of yarn evenness |

Carding, Winding |

| Wrap Block | HS-237 | Measurement of sliver & roving length |

Drawing, Roving |

| Roving Strength Tester | CAPA | Measurement of roving strength |

Roving |

| Single Strength Tester | Tensorapid 3 | Measurement of yarn strength |

Spinning, Winding |

| Yarn Fault Classifying Installation | Classimat 2.1 | Yarn fault test | Spinning, Winding |

| Twist Counter | 1200 rpm | Counting Twist | Spinning, Winding |

| Wrap Reel | HS-203 | Measurement of yarn length |

Spinning, Winding |

| Yarn Hairness Tester | G-565 | Yarn hairness test | Spinning, Winding |

| Yarn Inspector | 5-Position | Yarn | Spinning, Winding |

| Thermo-Hygrostat | HT-A 10GG2 | Temperature / Humidity control |

Testing Lab |

| Optical Microscope | Optiphot-2 | Ingredient Analysis | Yarn, Textile |

| Video Microscope | PICO | Defects Analysis | Yarn, Textile |